Exploring Biotechnology’s Positive Impact on Protein Fibre Fashion

Spiber, a bio-venture from Japan, is innovating in the textile industry by leveraging fermentation to produce fibers. The journey began in 2004 when bioinformatics researchers Kazuhide Sekiyama and Junichi Sugahara explored ways to create spider silk fibers through fermentation. Their findings laid the groundwork for addressing environmental challenges in textiles, allowing them to develop a unique protein specifically for high-end applications.

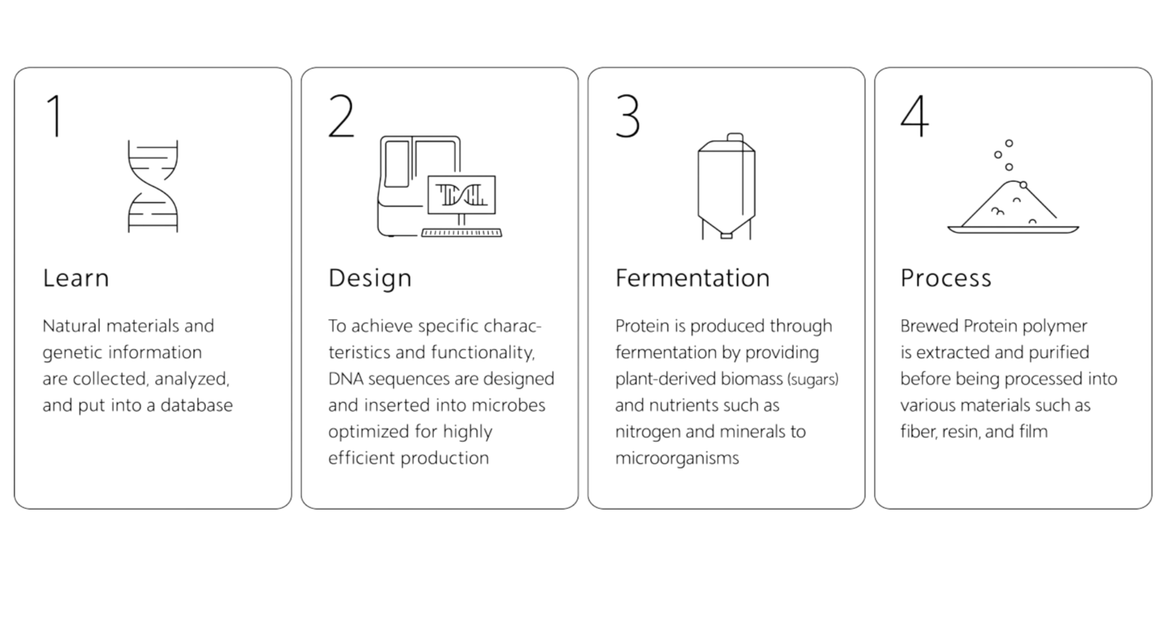

A decade back, Spiber achieved a significant milestone by producing Brewed Protein fibers. These fibers are biobased and biodegradable, resulting from inserting proprietary DNA into microorganisms to generate a designated protein, primarily using sugar sourced from sugarcane. Currently, Brewed Protein fibers are the only protein fibers recognized by ISO standards made through precision fermentation that are available on a large scale.

These fibers, available as staple fibers, tops/sliver, and spun yarn, feature a silk-like sheen alongside anti-odour and antibacterial properties. At the end of their life cycle, Brewed Protein fibers can decompose into nutrients, potentially serving as feedstock for producing additional Brewed Protein materials—a concept confirmed in laboratory settings.

2019 marked another breakthrough when Spiber and Japanese sportswear brand Goldwin unveiled the Moon Parka, the inaugural product made with Brewed Protein fibers. This successful collaboration was followed by partnerships with various prominent brands, including The North Face and luxury fashion labels like Pangaia and Sacai.

The versatility of Brewed Protein fibers allows for the creation of fabrics with elegant textures and enhanced functionalities. These fibers have shown to be anti-odour and antibacterial, adding to their appeal in the fashion industry. They can serve various applications, providing a blend of soft touch and durability, making them attractive for diverse apparel options.

2019 also marked Spiber’s entry into haute couture, as Japanese designer Yuima Nakazato began incorporating Brewed Protein fibers into his collections. Fast forward to July 2025, Dutch designer Iris van Herpen debuted a stunning bridal look made from Brewed Protein fibers during Paris Fashion Week. Ayana Nakajima, Spiber’s regional marketing manager, shared insights about the collaboration, its challenges, and what it means for the future of sustainable fashion.

Exciting collaborations in haute couture

The partnership with Iris van Herpen flourished naturally, as both parties share a dedication to sustainability and inspiration from nature. Although they recognized each other’s work for years, a mutual connection finally facilitated their collaboration. Their joint efforts emphasize the harmony between creativity, technology, and sustainability, illustrating how artistic vision can elevate material innovation.

A previous haute couture experience

Spiber’s connection to haute couture isn’t new; since 2019, the collaboration with Yuima Nakazato has pushed creative boundaries. He transformed aspects of the fibers that others deemed limitations, leading to the innovative textile modeling technique called biosmocking. This method imbues garments with depth and shape, showcasing the extraordinary potential of Brewed Protein materials.

His work showcases the potential of new materials and inspires others to examine and expand the possibilities of design.

Challenges in haute couture

For the collaboration with Iris van Herpen, the main focus wasn’t just on material performance. The aim was to explore how Brewed Protein materials can forge forms that are meticulously refined yet fluid, striking a balance between artistic expression and technical precision.

The resulting design combines structure with fluidity, reflecting an innovative synthesis of material advancement and design vision. This moment is not solely a runway presentation but a glimpse into the potential of marrying material innovation with creative artistry.

Spiber emphasizes the narrative capacity of materials, allowing them to evoke emotions and redefine our connections with the natural environment. This inaugural partnership with Iris van Herpen vividly illustrates these shared values in an extraordinary manner.

Feedback from industry partners

Brands and manufacturers that have utilized Brewed Protein fibers in their ready-to-wear collections have responded positively. The fibers, available in various forms, are often celebrated for their softness and overall comfort, which are crucial for apparel applications. One of Brewed Protein’s notable strengths lies in its adaptability: the aesthetics and textures of the fibers can vary based on their length, spinning technique, and fabric construction.

Through worsted spinning processes, the fibers can achieve a refined, shiny finish along with a smooth hand feel. The final fabric’s texture can significantly differ based on processing methods, thereby providing designers and manufacturers with a unique creative canvas.

Many partners have underscored the softness as a primary advantage, and discussions are ongoing about how Brewed Protein fibers can be blended with other materials for enhanced functionality. This represents an exciting journey of exploration that Spiber eagerly undertakes with its partners.

Learnings from developing Brewed Protein fibres

Spiber has discovered that the journey to create new materials demands extensive time and investment, especially when transitioning from small-scale lab prototypes to economic mass production. This scaling process requires not only technical breakthroughs but also a re-evaluation of business operations and supply chains. By managing the entire process of producing protein polymers in-house, Spiber is able to continuously refine and improve its offerings.

Looking forward, Spiber is keen on advancing sustainable production practices, including the use of non-edible feedstocks to redefine material innovation and contribute toward a more responsible manufacturing future.

Future collaborations and events

With over 80 companies, including textile mills, having worked with Brewed Protein fibers, and 45 brands launching more than 190 products utilizing this innovative material, Spiber is poised for further growth and collaborations around the globe.

As they continue expanding their collaborations in the US, Europe, China, India, Japan, and beyond, Spiber aims to partner with leading brands and manufacturers focused on accelerating the adoption of Brewed Protein fibers.

Upcoming events and showcases

Spiber is enthusiastic about upcoming participation in key events including Première Vision in Paris from September 16-18 and Biofabricate in London on September 16-17, 2025.

What lies ahead for Spiber?

As the first successful industrial producer of man-made protein fibers, including ISO 2076 certified Brewed Protein fiber, Spiber stands at the forefront of biomaterials in fashion and other industries. Their commitment to biotechnology drives their mission to reshape global industries while reducing environmental impacts.

Spiber continues to seek innovative applications for their materials to foster circular economies and advance systems that are both sustainable and regenerative. As the demand for protein-based materials rises, Spiber is designed to collaborate with progressive partners to transform material creation and usage in ways that benefit both people and the planet.

The interview was conducted in written format.